If there is cavitation for centrifugal pumps, it may cause vibration and noise during its daily operation, sometimes we may have to stop working. So we need to find what kind of reasons will lead to the cavitation for centrifugal pumps, then we could avoid these questions occurring very cleverly.

The cavitation of centrifugal pumps, or the cavitation , is a process for flow liquid bubbles and then burst. When the absolute speed of flow liquid increase, as the static pressure of flow liquid decrease, for certain particle at a certain temperature of the fluid , although there is no heat from external input, but they have reached the vapor pressure, so that particle vaporization, and the bubble generated. Along the flow path.

If the static pressure of the fluid will be increased again, higher than the vapor pressure, the bubble will burst very quickly. A huge part of the condensation implosion impact. If the bubble burst when not in the flow of the liquid, but in the wall of the guide assembly parts, the cavitation will lead to the wet parts subjected to erosion.

When centrifugal pump works at the condition of cavitation, even if there is no wet parts erosion , you could also find that at this time the noise of centrifugal pump is very big, vibration intensifies, efficiency decrease, and the head will become very low accordingly.

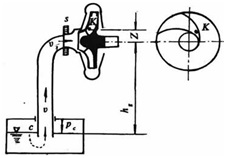

The equipment NPSHa , also called as effective NPSH. The equipment is provided by suction equipment, in the suction position of centrifugal pump, unit weight of the liquid have surplus energy more than vaporization pressure and head . Overseas call this an effective net positive suction head, That pump inlet (head position is zero) with a full head of liquid minus vaporization pressure and the net surplus value, represented by NPSHa. Its value and parameters related to liquid properties. Because inhalation device is proportional to the square of the flow and hydraulic loss. So NPSH decreases with the increase in capacity. NPSH-Q is a decreasing curve. The NPSH have relationship with the flow condition of pumps, it was balance pump inlet pressure drop decided by centrifugal pump itself. That is to say, in order to avoid the cavitation for the pump, we require that there is extra energy that could exceed vapor pressure head in the pump inlet. Overseas call this a required net positive suction head. The physical meaning of the pump NPSH indicates the degree of pump inlet pressure drop of the liquid. The so-called net positive suction head required, It is to require the inhalation device must be provided such a large net positive suction head, in order to compensate the pressure drops, to ensure that the pump cavitation does not occur.

NPSH of multistage centrifugal pump have no relationship with equipment parameters. Only related to motion parameters in pump inlet. Motion parameters at a certain speed and flow parameters are determined by the geometry. That is to say, NPSH is determined by the pump itself. For a given pump, regardless of the liquid, At a certain speed and flow through the pump inlet, therefore, due to the same speed so they have the same pressure drop, same NPSHr. So NPSHr have no relationship with fluid properties. NPSH smaller, the smaller the pressure,

Ti requires the equipment must provide smaller NPSHa, and then a better resistance for pump cavitation.

Post time: Jun-11-2021