05 July 2025

(sludge pump types)

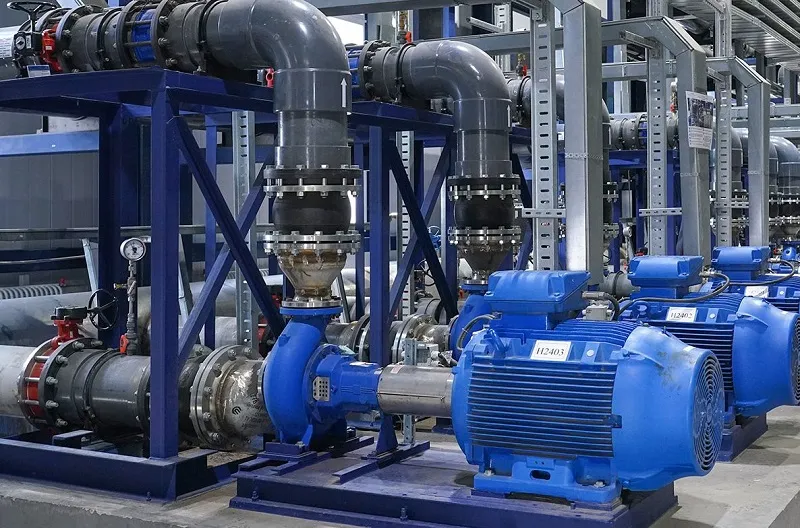

Sludge pump types have become a cornerstone in various industries where the efficient transfer of viscous, abrasive, and solid-laden fluids is a daily challenge. Water treatment plants, mining operations, municipal wastewater systems, oil & gas refineries, and chemical manufacturing all rely on specialized pumps to keep processes efficient and safe. The market for sludge pumps alone reached $420 million globally in 2023, according to industry reports, underscoring their widespread adoption. These pumps are meticulously engineered to handle everything from raw sewage to abrasive slurries and dewatering tasks, ensuring reliable operation in the harshest environments. Understanding the range and functionality of these pumps allows operators to minimize maintenance, reduce energy consumption, and maximize uptime.

Distinguishing slurry pump types and types of slurry pumps involves considering several classifications based on application, construction, and operational principle. The four primary types include:

The right selection depends on metrics such as viscosity, solids percentage, head pressure, and abrasion level. For example, mining facilities handling 60% solids by weight prefer robust positive displacement units, while civil projects may benefit from rapid-deployment submersible solutions.

The leap in engineering over the past decade has amplified the efficiency of all types of slurry pumps. Recent data from the Pump Manufacturers Association illustrates that leading centrifugal models now deliver up to 89% hydraulic efficiency, with operational lifespans exceeding 25,000 hours in moderate abrasion environments. Key technical features include:

In highly abrasive conditions, proper selection based on material compatibility and custom impeller design can boost reliability and total cost of ownership over the pump’s working life.

| Manufacturer | Key Pump Type | Maximum Solids Handling (%) | Abrasion Resistance Rating | Energy Efficiency (%) | Mean Time Between Failures (hours) | Warranty (years) |

|---|---|---|---|---|---|---|

| Xylem | Submersible Centrifugal | 70 | 8/10 | 86 | 19,000 | 3 |

| Weir Minerals | Horizontal Slurry | 65 | 9/10 | 89 | 25,000 | 2 |

| KSB | Vertical Slurry | 60 | 9/10 | 87 | 22,500 | 2 |

| ITT Goulds | Progressive Cavity | 65 | 7/10 | 85 | 21,000 | 2 |

| Verder | Peristaltic | 72 | 7/10 | 83 | 18,500 | 2 |

The table above highlights the leading manufacturers in the market, focusing on their signature sludge pump types and critical performance metrics. Notably, Weir Minerals and Xylem lead on efficiency and robust design, while Verder offers market-leading solids handling and precision. These data points enable procurement teams to drive value-based selections based on actual operating conditions rather than generic catalog specifications.

No two process streams are identical—custom slurry pump types have become an industry standard for applications demanding unique flow rates, chemical resistance, or space constraints. For instance, food processing plants frequently require FDA-approved elastomer internals, while flue gas desulfurization (FGD) units in power plants depend on specialized corrosion-resistant linings such as duplex stainless steel. Up to 45% of heavy-industry installations in 2023 featured semi-bespoke pump assemblies, tailored according to pipeline configuration, NPSH constraints, and modular system integration. Software-driven design simulation, rapid 3D prototyping, and modular wet ends now allow for lead times as short as 4-6 weeks for non-standard builds. Custom monitoring suites and remote diagnostics further ensure pumps operate within optimal envelope, reducing energy costs by up to 20% for some bespoke systems. This commitment to customization empowers operators to transcend one-size-fits-all limitations and optimize total system performance.

Real-world case studies validate technical expertise, ranging from municipal sewage projects to complex mining operations:

These documented outcomes confirm that technical choice and proper customization are key to achieving operational excellence with types of slurry pumps in demanding environments.

Making informed decisions about sludge pump types is critical to maintaining both efficiency and cost-effectiveness in industrial and municipal settings. Whether the requirement is for maximal solids handling, high abrasion resistance, or advanced sensor integration, the contemporary marketplace offers a spectrum of pump types suited to every application profile. Data-driven manufacturer benchmarking, technical customization, and firsthand success stories all lead to one conclusion: selecting the best-matched pump requires a holistic view of both performance metrics and site-specific demands. As industries continue to modernize, integrating advanced slurry pump types represents a forward-thinking investment in reliability, safety, and long-term value.

(sludge pump types)

This is the first article